3D Scan to Print

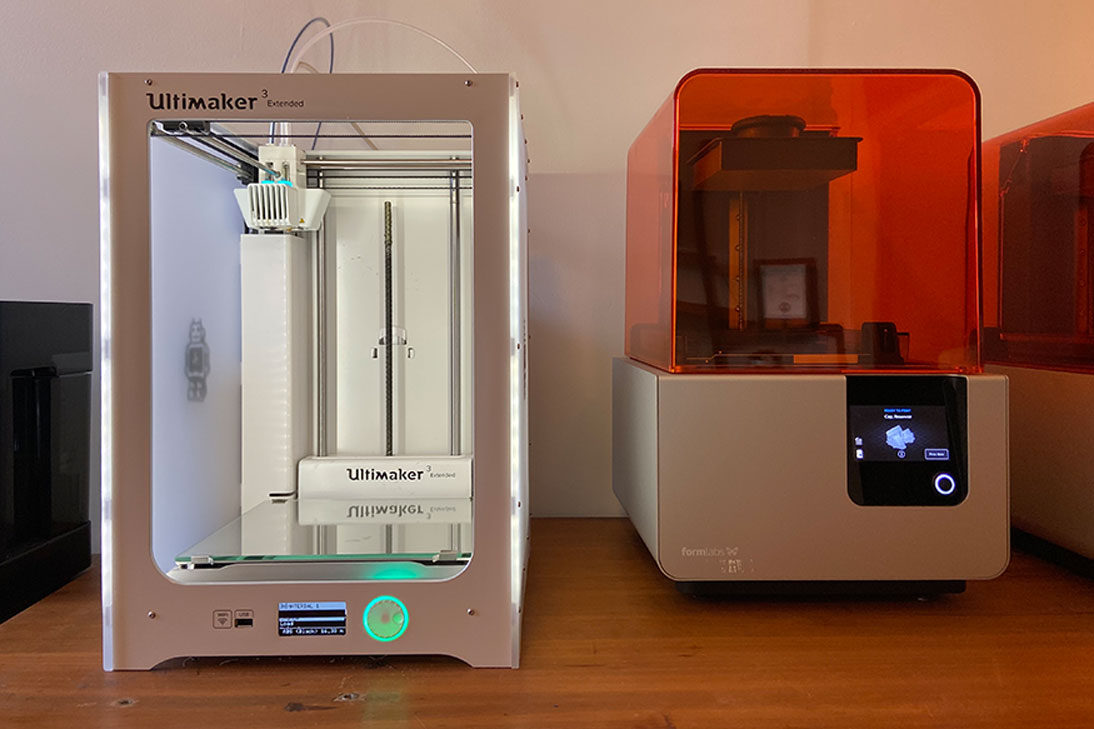

Tools

The Basics

The world of 3D scanning has grown to include hobbyist level equipment all the way to full room setups that capture digital imagery for blockbuster films. All of this 3D data and visualization can be used to create geometries that can be 3D printed. From scanning your favorite pet and creating figurine for your desk or reverse engineering a engineering part, 3D scanning and 3D printing can be used together to rapidly create new ideas.

This article will overview common 3D scanning equipment, especially entry-level and will talk through the common file outputs and how to prep them for 3D printing.

3D Scanning Basics

3D scanning works by capturing visual data with a camera and converting it into a 3D Mesh of digital data. The hardware and software of 3D scanners work together to translate geometry into a digital mesh of the physical shape and color. More expensive equipment has a greater resolution or in other words can create a more detailed and exact match of a physical object. 3D Scanning has evolved to include tracking motion but in the terms of 3D printing we will focus on static objects.

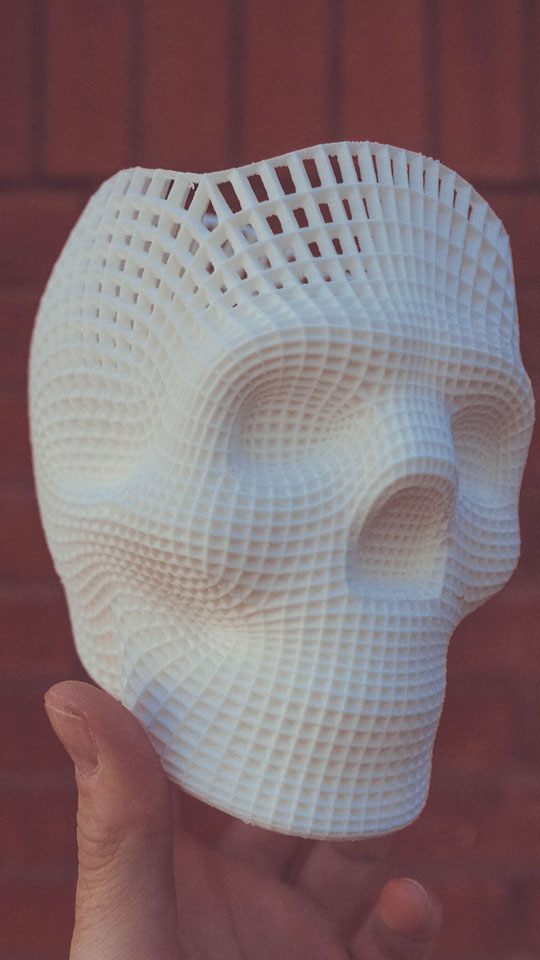

Once an object has been scanned 3D software inerprates the data in the form of a mesh. This mesh uses polygons to give the model a surface, the more polygons a model has the more fine detail it can pick up. Sometimes there are broken areas or missing parts to a mesh which most softwares help you to repair and close so you are left with a solid model.

Poly Models

The final solid model that you’re left with, once the mesh is closed and “water-tight” or complete solid and if you can imagine it wouldn’t allow water to leak out of the mesh, is a poly-based 3D model. Common file types would be STL, OBJ, or 3DS. These models are perfect for 3D printing as most printers on the market work directly with this file type.

Getting Ready to Print

Once you have closed the mesh on your part and it is water-tight, it’s time to jump into 3D Printing. Upload your part directly to the Fictiv platform and choose the type of material that best suits your project. Keep in mind the scale of your object when uploading it for printing as you may want to scale up or down based on the size of your scan.

If your part looks pixelated in the 3D viewer, you may want to increase the resolution of your scan and the number of Polygons. Fictiv can import up to 100MB so don’t be afraid to increase your file size to capture as much data as possible.

3D scanning is a great tool to use when it comes to reverse engineering or creating models of real life object. For more information on how to upload your files and getting started with 3D Printing, check out the article on importing files here.

Opens in new window Contact us to learn more.